For Manufacturing Companies and Machine Builders

Integrate any machine, even legacy or dark machines

Build a secure and flexible data integration layer

Use open standards to avoid vendor lock-in

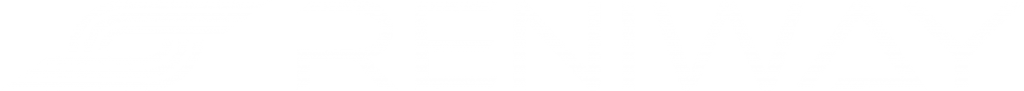

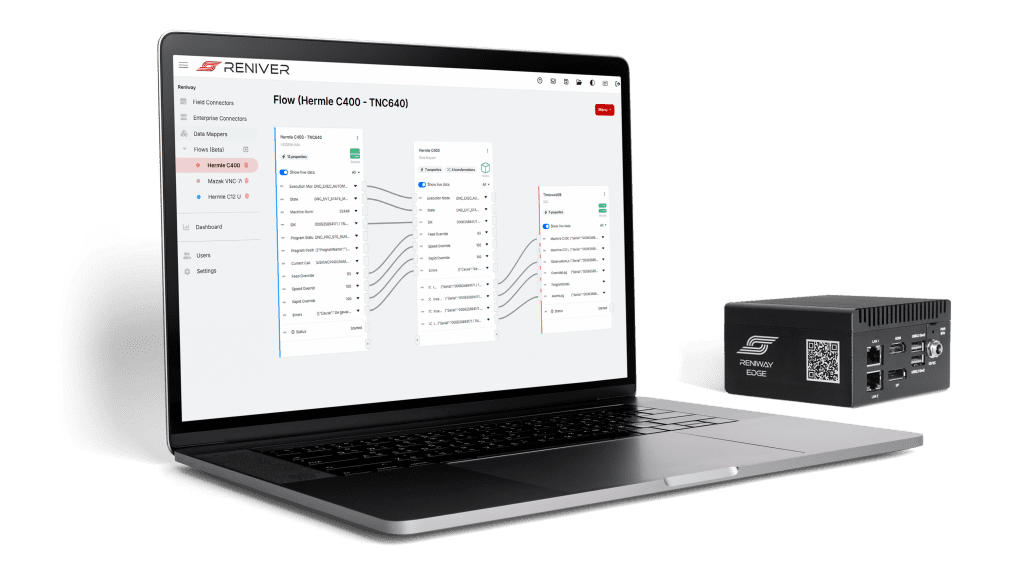

Available as Reniver IPC Edge device or Docker installation. Contact us for more information.

Easy data-integration for your existing business software or platforms

Cybersecurity built-in

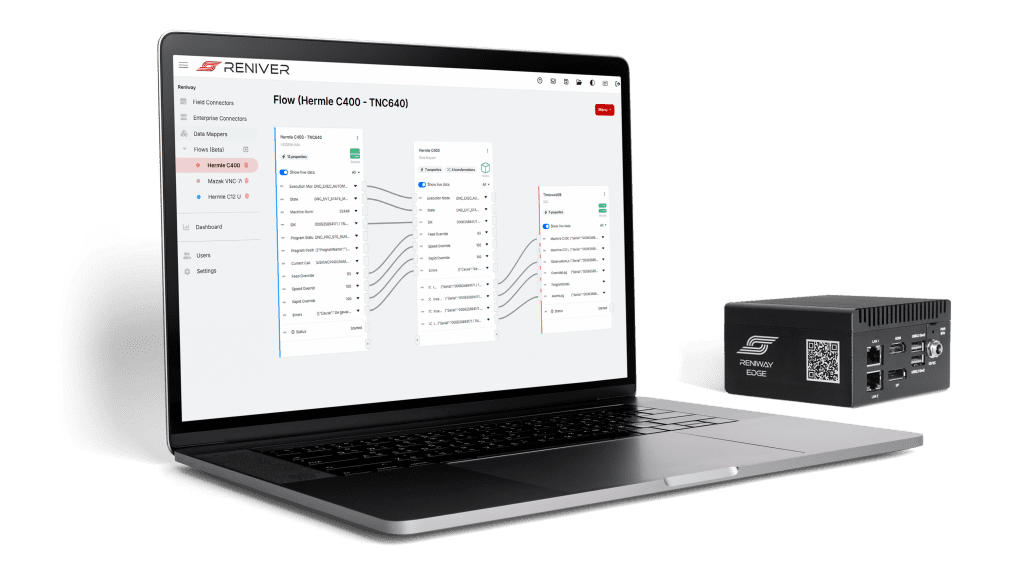

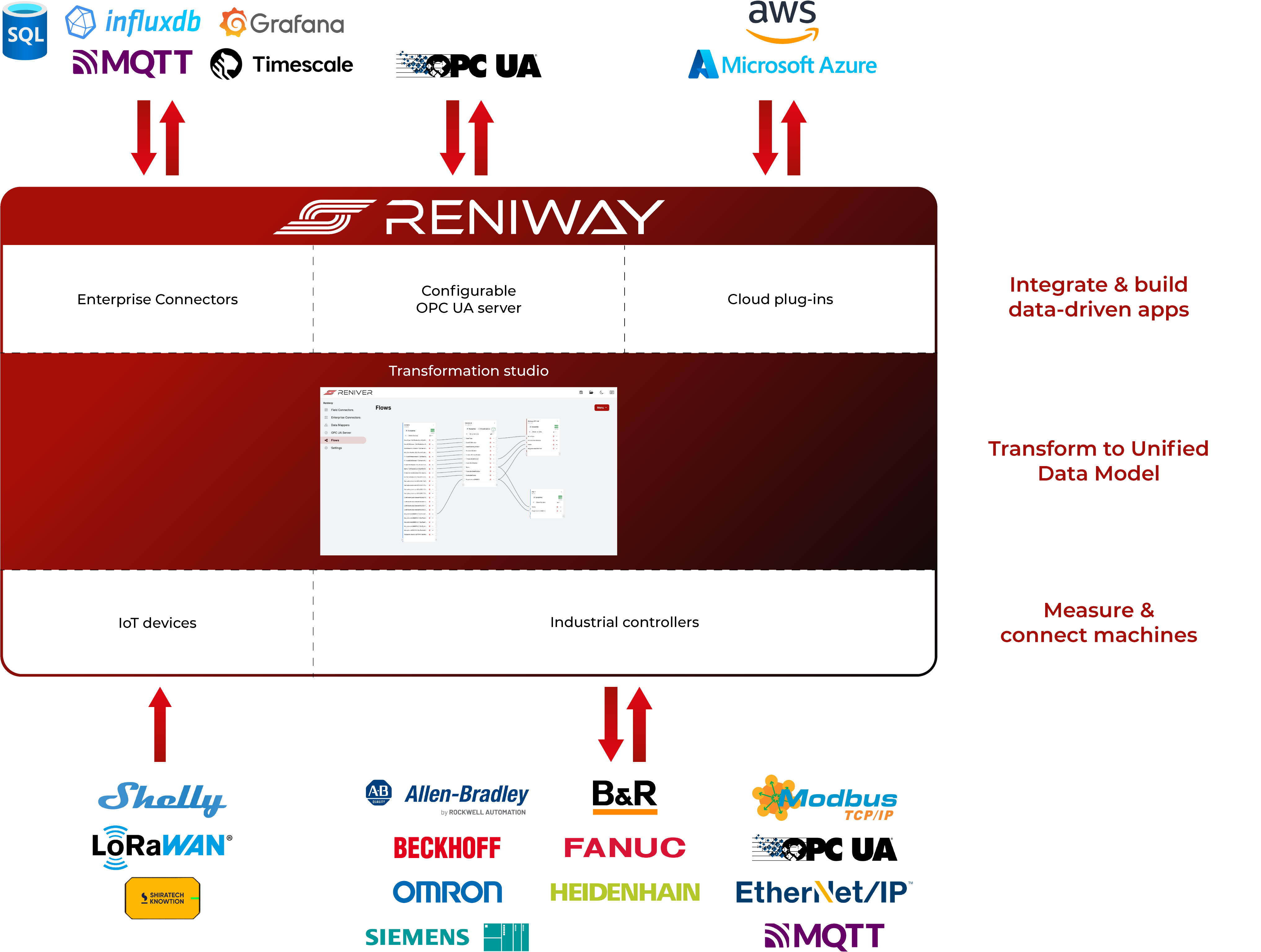

Reniway is a powerful platform designed for you to seamlessly connect your machines, transform and standardize raw data, and provide actionable analytics. Whether you need to integrate legacy machines or modern equipment, Reniway bridges the gap, making your data work for you.

Reniway is a powerful platform designed for you to seamlessly connect your machines, transform and standardize raw data, and provide actionable analytics. Whether you need to integrate legacy machines or modern equipment, Reniway bridges the gap, making your data work for you.

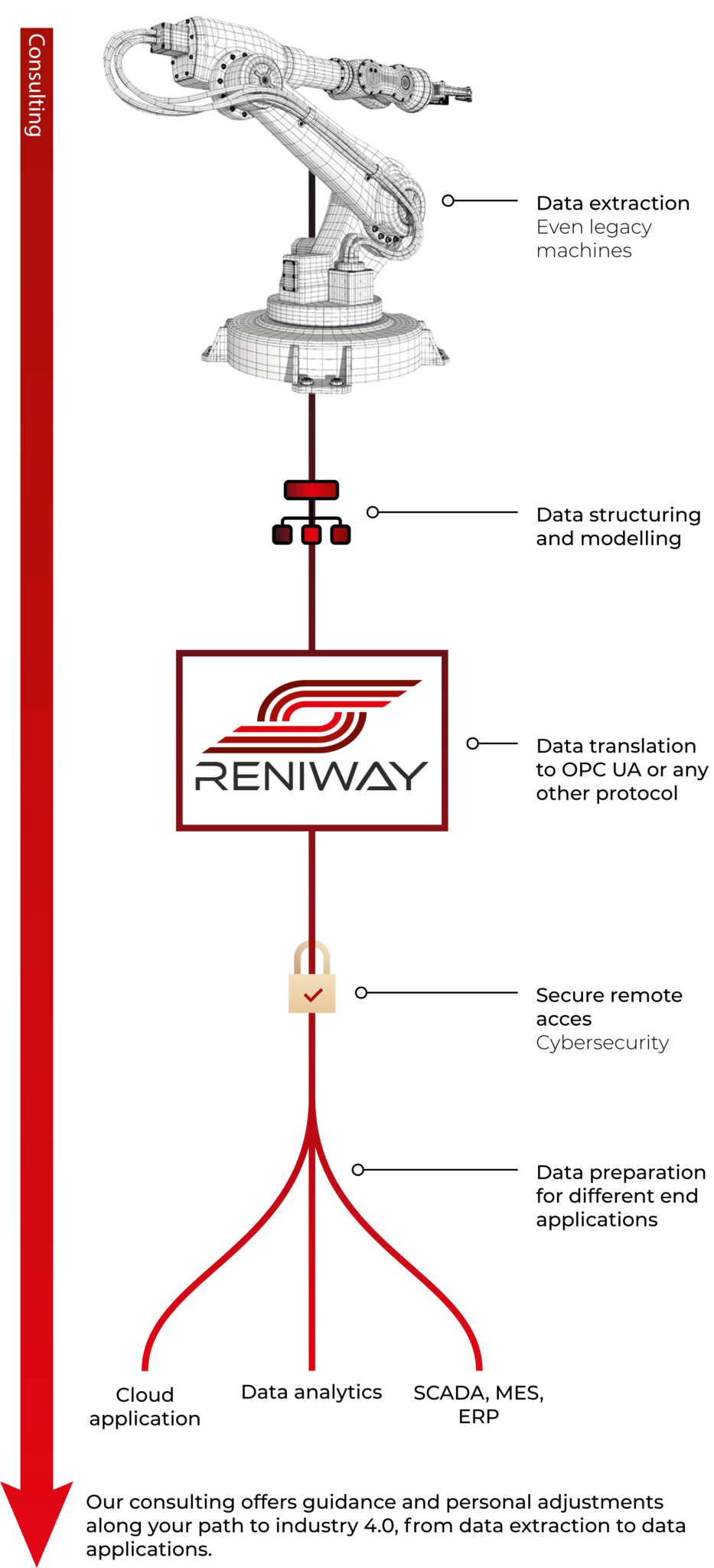

Reniway seamlessly connects to any industrial device, regardless of age or protocol, ensuring smooth data acquisition from a diverse range of machines.

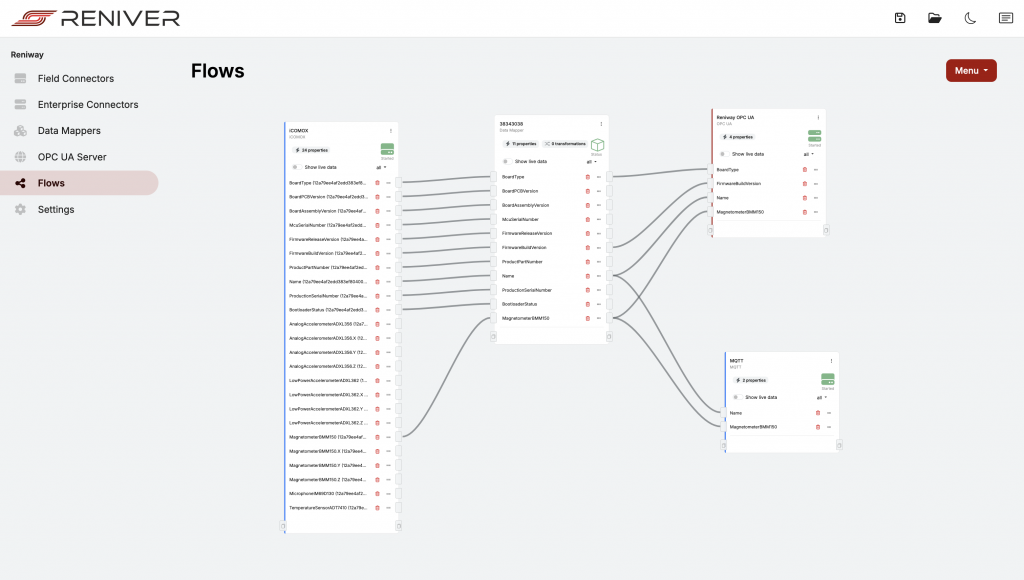

Once connected, Reniway maps and organizes data into a unified model, simplifying integration and making it compatible across different systems.

Finally, the data is transformed and standardized to your desired format, enabling consistent, reliable communication with automation systems and IT networks.

With every Reniway installation, it’s possible to unlock

data-driven use cases such as:

Connect

Reniway seamlessly connects to any industrial device, regardless of age or protocol, ensuring smooth data acquisition from a diverse range of machines.

Unify

Once connected, Reniway maps and organizes data into a unified model, simplifying integration and making it compatible across different systems.

Transform and Standardize

Finally, the data is transformed and standardized to your desired format, enabling consistent, reliable communication with automation systems and IT networks.

With every Reniway installation, it’s possible to unlock

data-driven use cases such as:

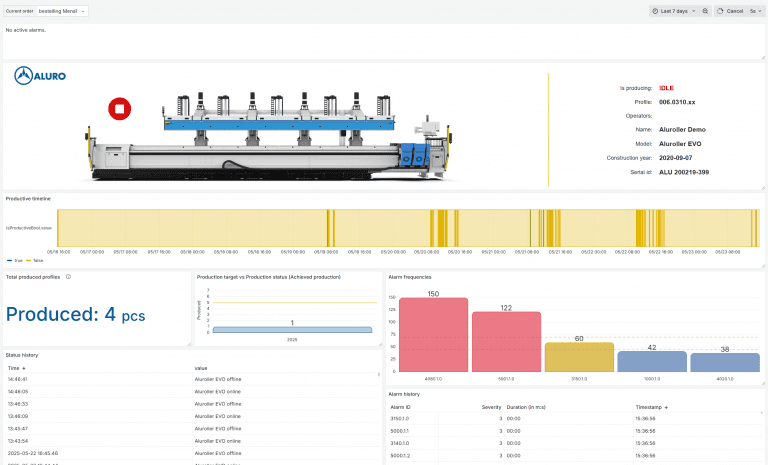

Enabling a smart and standardized interface for aluminium roller machines

Aluro Machines

Aluro designs and builds advanced machines for processing aluminum profiles, with a strong focus on thermal break insertion and automation solutions for extrusion companies worldwide.

As their customers modernize operations, there is growing demand for machines that not only perform mechanically but also integrate digitally with MES, ERP, and monitoring systems. However, the customized nature of Aluro’s machines makes it difficult to standardize data and create plug-and-play digital interfaces. This complicates integration and limits opportunities for remote diagnostics, predictive maintenance, and scalable after-sales services.

Every company has unique needs, and the benefits of Reniway vary depending on your industry and use case. Whether you’re a manufacturing company looking to optimize production, a CNC manufacturer aiming for better process control, or a machine builder enhancing after-sales service, Reniway provides tailored insights and efficiency improvements to fit your operations.

Integrate any machine, even legacy or dark machines

Reniway seamlessly connects to any machine, regardless of age or technology, using flexible data mapping and standardization. This ensures all machines, even those with proprietary or outdated protocols, can contribute valuable data to your digital ecosystem.

Reduce integration costs with a secure and flexible data integration layer

By building a robust, scalable integration layer, Reniway simplifies the process of connecting multiple systems. This reduces the need for expensive custom development and ensures secure, streamlined data flow.

Quickly capture datasets for data-driven apps, digital twins, and AI

Reniway facilitates the fast, accurate collection of machine data, creating standardized datasets ready for use in analytics, digital twin technology, and AI applications. This accelerates digital transformation projects and enhances operational insights.

Avoid vendor lock-in with open standards

Accurately log manufacturing times and production parameters for each product. This comprehensive data trail enhances insight into production quality, ensuring you have complete control over your manufacturing process and product traceability.

Insights into production piece & changeover times

Gain precise visibility into the time it takes to produce individual parts and complete machine changeovers, enabling you to optimize scheduling, minimize delays, and improve overall production efficiency.

Comparing planning vs actual production times

Analyze discrepancies between planned and actual production times to identify inefficiencies, improve resource allocation, and enhance the accuracy of future planning processes.

Alarm responses

Centralized alarm management ensures that faults are addressed promptly. Quick responses to issues reduce downtime, leading to more consistent production and a boost to your bottom line.

Tool data

Monitor tool usage, wear, and performance in real time to extend tool life, reduce downtime, and ensure consistent production quality.

Optimized Traceability

Accurately log manufacturing times and production parameters for each product. This comprehensive data trail enhances insight into production quality, ensuring you have complete control over your manufacturing process and product traceability.

Quick and easy automation/MES integration for your machines

Reniway integrates your machines with client automation systems and MES, using data mapping for seamless connectivity. Its quick setup saves time, letting machine builders focus on designing machines rather than data extraction.

Remote diagnostics and monitoring for better support

With Reniway, you can access real-time machine data remotely, enabling efficient diagnostics and proactive support. This minimizes on-site visits and helps resolve issues faster, improving overall machine uptime.

Automatic configuration of OEE dashboards and maintenance notifications

Reniway automates the setup of OEE dashboards and maintenance alerts, providing instant insights into machine performance and health. This helps manufacturers stay informed and take timely action to optimize productivity.

Quickly capture datasets for data-driven apps, digital twins and AI

Easily collect and standardize data from various machines, making it ready for advanced applications like digital twins, AI models, and analytics. This feature accelerates digital transformation projects and innovation.

Built-in connectors

In need of your own custom connection? Contact us to discover the possibilities

Explore how our Reniway Edge software works through this 3-part online demo:

Download your personal demo license and get 30 minutes of full platform access. Need more time? Just restart the session — as often as you like.

Fill in your contact details to get started. Want to dive deeper?

Check out our technical documentation and user tutorials ›

What can you expect?

Become Reniver’s C++ master! Work closely with real machines, industrial equipment, and real-time systems like PLCs or RTOS edge devices. Design, build and maintain high performance microservices that capture, transform, and store data from industrial controllers, IoT devices, robots, etc. By using model-based design and tools you turn data models into generated code fast-tracking your development. Your code will be reviewed, built, tested, and deployed using Gitlab DevOps tooling, Linux, and Docker technology.

Your profile

We are always on the lookout for Mister Jack, the Jack of all trades. However, if you are familiar with any of the technologies listed below, please feel free to contact us:

Or if you’re looking to learn any of these skills quickly, we invite you to apply now!

Full-Stack Developer | C# .NET Angular

What can you expect?

Become the star developer of our state-of-the-art Reniway application! Design and implement microservices with REST APIs, IoT communication services and function blocks for our low-code platform using C# .NET6. A nicely built and architected backend goes hand-in-hand with a great user experience, for which you will develop the Reniway UI Angular 15 with Material app. Your code will be reviewed, built, tested and deployed using our Gitlab DevOps tooling and Docker technology.

Your profile

We are always on the lookout for Mister Jack, the Jack of all trades. However, if you are familiar with any of the technologies listed below, please feel free to contact us:

Or if you’re looking to learn any of these skills quickly, we invite you to apply now!

Data Engineer | Digital Manufacturing Platform | Lier

Wat kan je verwachten?

Je werkt mee aan onderzoek en ontwikkeling van een innovatieve “Industrie 4.0” oplossing die productiedata slim inzet om efficiënter te produceren en proactieve acties te nemen om stilstand te verminderen. Het kantoor ligt bij het pittoreske centrum van Lier en is goed bereikbaar via openbaar vervoer. Je komt terecht in een informele werksfeer met een jong en gedreven team. Je werkindeling bepaal je zelf en thuiswerk is helemaal ingeburgerd.

Jouw profiel

Onze witte raaf kan alles, maar ben je vertrouwd met 1 of meerdere van onderstaande technologieën, aarzel dan zeker niet om ons te contacteren:

of enkele van deze skills snel wil bijleren. Dan nodigen we jou graag uit om te solliciteren!

Devops | Digital Manufacturing Platform | Lier

Wil je graag werken in de wereld van machinebouwers, smart factories en Industrie 4.0? En zie je jezelf groeien in een jonge onderneming vol enthousiasme, waar je de kans krijgt om je huidige software skills verder te ontwikkelen?

Dan willen we je leren kennen!

Wie zijn wij?

Een innovatief technologiebedrijf dat oplossingen biedt om machinebouwers en productiebedrijven klaar te maken voor de connected future. Onze ingenieurs en programmeurs realiseren projecten die bestaan uit een combinatie van consultancy, software ontwikkeling op maat en ons in-house ontwikkeld product (machine connectivity platform). We hebben sterke groeiambities en zijn daarom op zoek naar meerdere ontwikkelaars.

Wat kan je verwachten?

Je werkt mee aan onderzoek en ontwikkeling van een innovatieve “Industrie 4.0” oplossing die productiedata slim inzet om efficiënter te produceren en proactieve acties te nemen om stilstand te verminderen. Het kantoor ligt bij het pittoreske centrum van Lier en is goed bereikbaar via openbaar vervoer. Je komt terecht in een informele werksfeer met een jong en gedreven team. Je werkindeling bepaal je zelf en thuiswerk is helemaal ingeburgerd.

Wat bieden we aan?

Een aanstelling met een voltijds contract, een goede verloning met extra legale voordelen. Twaalf ADV dagen boven op je wettelijk verlof. Je werkt zelfstandig in alle flexibiliteit. Verder kan je genieten van een ruim opleidingsbudget op maat om je start optimaal te begeleiden. Je bouwt aan de groei van het bedrijf en deelt in het succes.

Jouw profiel

Onze witte raaf kan alles, maar ben je vertrouwd met 1 of meerdere van onderstaande technologieën, aarzel dan zeker niet om ons te contacteren:

of enkele van deze skills snel wil bijleren. Dan nodigen we jou graag uit om te solliciteren!